|

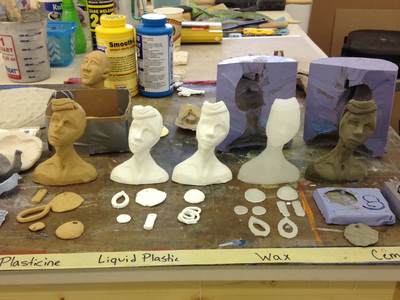

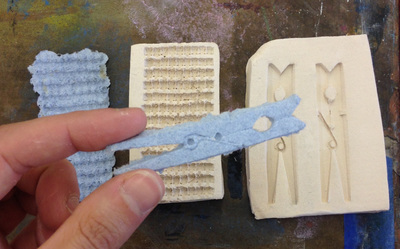

My main goal while attending workshops at Arromwont this summer was to learn things I had never experienced before and that were slightly outside my material, but that I could continue to incorporate into my work once returning to UF. The second workshop at Arrowmont was Mold Making with Paul Andrew Wandless where we practiced techniques of creating latex molds, silicone rubber molds, and casting wax, cement, plastic, and paper pulp press molds. I learned many valuable techniques that I can continue to use in making my own work. I had never really had the opportunity to learn much about mold making prior to this and Paul was a fantastic instructor and this course was actually the first time he combined all of these techniques into one workshop. He has taught many workshops, but typically when Paul teaches a mold making course, plaster and rubber are separate workshops. I admired his ability to fit in so many mold making practices in such a short period of time! There was also great collaboration between a lot of the workshops and instructors that week which allowed us the chance to incorporate paper pulp into our work. I will attempt to consolidate all that I learned into images throughout this post. You can click on the images to read the description…. Plaster Mold Paul taught me a different method of plaster molds. Usually one is taught the “island” technique of plaster mixing. His was the method of weighting the plaster and water. Rubber Latex Mold One of the first materials we worked with to create molds was rubber latex (Rub-R-Mold). This type of mold is great for one part molds, small objects, and ones with complex forms. The valuable characteristic about a rubber latex mold is its ability to be flexible. It can be turned inside out, twisted, popped, and causes no damage to the mold if made properly. This allows for complex forms casted to be removed with ease. Paul had us bring with us small objects that were fairly complex so that we could learn the techniques necessary for mold making. I brought a small pendant and a sculpture of a toro. You can use this with leather hard or bisque ware as well. Silicone Rubber Mold We used many different products to create molds and the Silicone Rubber #30 by Smooth-On was very effective. Our first task was to create a plasticine form to create our mold from. We used chip board again to create a barrier for our mold and once poured it took about 6 hrs to cure, but I let it sit overnight. Wax, Liquid Plastic, and Cement Casting We used our Silicone Rubber mold to create many types of castings. White Liquid Plastic #300 by Smooth-On was used. We also learned to cast Wax (Paraffin) and Cement (Quikrete.) A neat trick when casting the liquid plastic is to pour water in the mold first so you can determine how much material you may need to mix up. Always use gloves when mixing the plastic! If you plan to paint your plastic you can apply a thin layer of gesso to the surface to help many paints adhere to the surface. You will want a cement with no large particles and no aggregate! If you are creating outdoor sculpture you can add a fortifier to strengthen your cement. Paul stressed that you store your molds together so that the surface inside does not change and that the mold continues to fit together properly. Paper Pulp Press Molds We created press molds and plaster molds to cast paper pulp. I found the bisque press molds to be more effective than the plaster molds. They seemed to dry out the paper faster, where the plaster castings took much longer to dry. You can also use the latex mold but the moisture must be sponged out since it is not absorbant. Once the paper has dried completely it is surprisingly very durable! Paper pulp can be created by many materials. You can use paper towel and toilet paper as a cheaper material. We created molds from cotton, denim, and old t-shirts too but those were mixed with the proper machine and technique. The paper towel and toilet paper can be mixed with a basic blender and water. The paper will only adhere properly if you consider it like clay. The pulp must be of the same consistency and with similar amounts of water for them to bond strongly. Some References From Paul... 1/22/2020 07:10:57 pm

Hello Stephanie, those are really impressive mold making. I was looking for ideas on how to do this and this is a really great to start. Now all I have to do, to get started is to look for a great sculpture supply for my new found hobby. Thanks for imparting ideas and I hope that other readers will find this article informative.

Hello Comments are closed.

|

|

RSS Feed

RSS Feed